Our sustainability projects

Our sustainability projects are central to our holistic sustainability management. We strive to ensure that every action we take has a positive impact on the environment, the economy and society. Below we present some current example projects from 2023 and 2024 in the areas mentioned:

Ecology

The biomass heating plant

Why are we building a biomass heating plant?

Here are the facts about our major project on Lüscher Strasse:

- An important step towards decarbonisation (reduction of CO2 emissions)

- Security of supply for the operational energy supply

- The fuel is biomass in the form of waste wood classified as A1 + A2 (industrial waste wood and used wood)

- Heat is generated in the form of saturated steam, which is supplied to the production plants via the steam network, this saturated steam is intended for high-temperature applications such as peeling and frying potatoes

How does it work?

The waste wood is stored in a closed storage building with an air filter. This means neither dust nor odours get outside. Mechanical processing takes place before delivery. Metal parts etc. are automatically sorted out during the transport of the waste wood from the fuel store to the biomass boiler is automatically sorted out. The waste wood is then burnt in a biomass boiler at 850 - 950 degrees. The hot exhaust gas from the combustion heats water in a steam boiler water into saturated steam. This saturated steam is made available to production as an energy source via a pipe route.

Social

Construction of a primary school and other facilities

In August 2023, we initiated the construction of a primary school together with the Reiner Meutsch Foundation FLY & HELP. This school is being built in Makuyuni Juu, a suburb of the main village of Makuyuni, located in the Monduli district and the Arusha region of Tanzania. Initially, we are focussing on the construction of two classrooms, an office and separate sanitary facilities for girls and boys. In addition, a rainwater collection system will be installed. Thanks to our financial support, the classrooms and the office will also be equipped with furniture.

The plan is to gradually expand the school over the coming years. It will open up a multitude of opportunities and possibilities for future generations. The project will be realised over a long period of several years. It is planned to expand the project in the future and create around eight classrooms, a staff room and a teacher's house in several stages.

The school will be called "Wernsing" and aims to make education accessible even in the most remote regions of Tanzania. The opening ceremony of the "Wernsing School" took place in February 2024 and was a great success, with the children's enthusiasm being particularly noticeable.

Economy

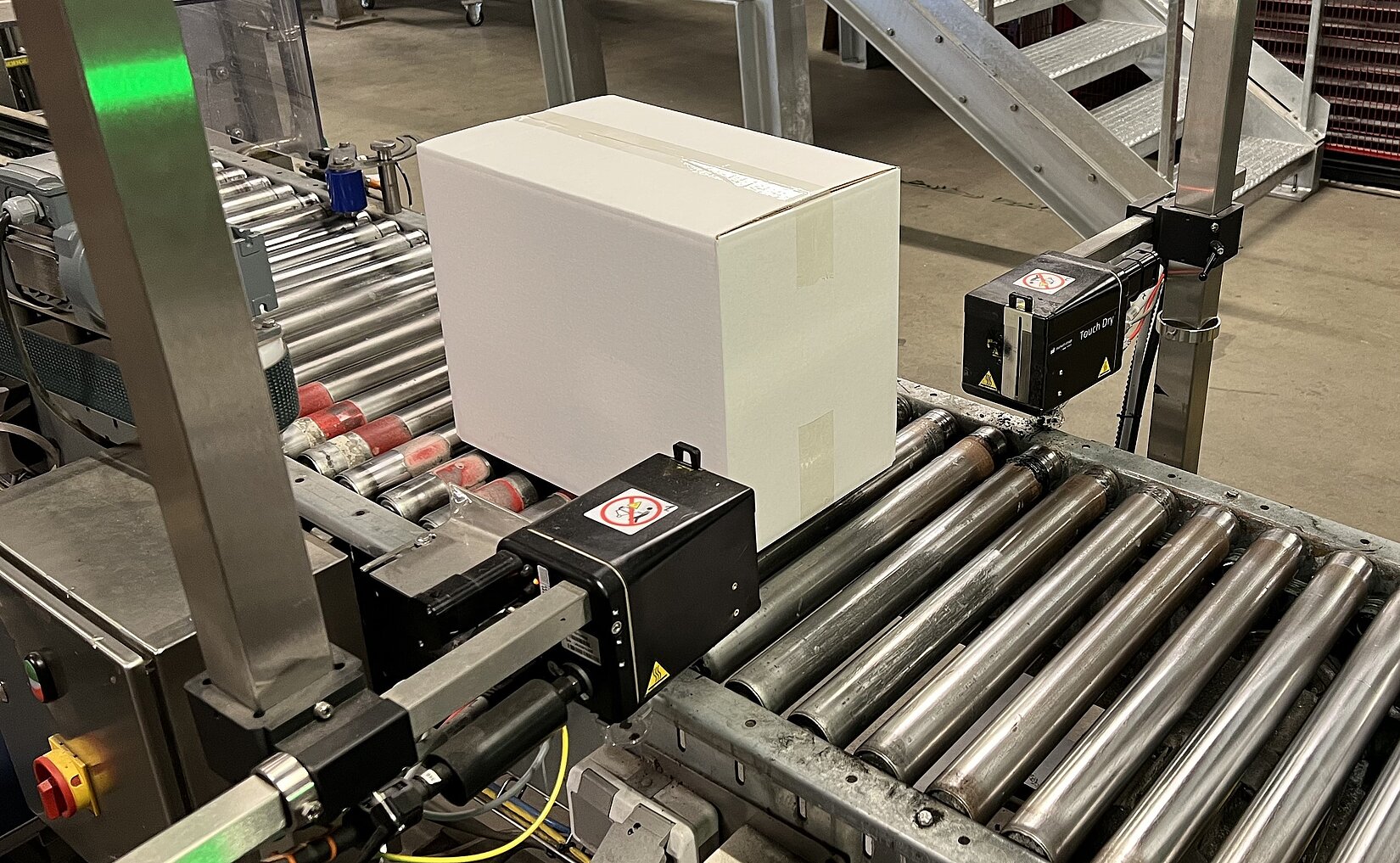

Direct printing on cardboard

One of our innovative projects in 2024 is direct printing on cardboard. The idea behind this is to print the most important information about the product directly on the carton instead of sticking printed labels on four sides of the carton.

This offers many advantages, particularly for the economic pillar:

By eliminating the label rolls, many material costs are saved. In addition, the new printer is more compact than the four-sided labeller, meaning that less space is required for installation. It should also be emphasised that direct printing allows more information to be applied to the cardboard, as there are no restrictions due to the label sizes. The wax can be topped up during production, eliminating production downtime for label roll changes and reducing the need for cleaning intervals.

In addition, this innovation also has a positive impact on the ecological and social pillars. Several hundred thousand labels are saved every month and an environmentally friendly and solvent-free wax is used for printing instead. Recycling the printed cardboard is easier as the cardboard does not have to be treated separately. In addition, CO₂ emissions are reduced due to the lower logistical effort. Employees benefit from the more efficient way of working, as they no longer have to invest so much time in labelling logistics.

The direct printer is currently being used in this form in a department that packs assortment cartons for food retailers.